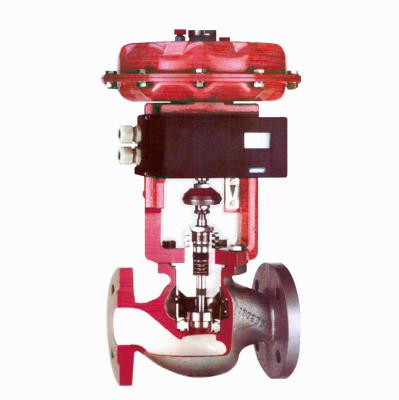

Reliable Stem Seals:

From The Stuffing Box To The Hermetically-Sealed Bellows, This Stem Seal Can Be Tailored Exactly To The Process Fluid, Pressure, And Temperature Required. The Design, Stem Surface, And Packing Material Complement Each Other Perfectly To Avoid Problems With Friction, Corrosion, And Emissions.

Fixed-Form Housing Seal:

Our Design Connects The Valve Housing And The Bonnet In The Force Bypass, And The Housing Seal Is Clamped In Place Preventing It From “Yielding”.

Robust, High-Precision Valve Trims:

These Are Specially Designed For The Prevailing Flow Conditions In Your Plant. The Shapes Of The Throttle Valves And Valve Seats And The Material From Which They Are Made Are Optimized To Meet Your Requirements. Our Valve Seats Integrate The Unique Quick-Exchange System And Can Be Replaced Without Special Tools. The Float-Mounted Clamping Seat And The Metal Or Soft Seal For The Valve Seat Ensure Leak-Tight, Reliable Sealing.

We Innovate, You Benefit!

Patented Valve Seat With PTFE Soft Seal And Metal Secondary Seal:

– Absolute Seat Tightness

– Defined Preload

– Long Service Life

Symmetrical Seat Rings Made From A Wide Variety Of Materials:

– Reproducible Seat Tightness Due To Self-Centering

– Low Wear And Tear Minimizes Cost Of Spare Parts

PTFE V-Ring Packing With Additional Precision Sealing Element:

– Safety And Hermetic Sealing

– Low Maintenance

Double-Life Quick-Exchange System For Seat Rings And Plugs:

– Maintenance Without Special Tools

The Wide Variety Of Valve Trims Optimised For All Applications:

– Maximum Process Flexibility With High Control Quality

– Low Noise Emissions

Valve Plug And Stem Can Be Replaced Separately:

– Reduced Storage

– Cost-Effective Plug Replacement

Flow-optimized Valve Housing:

– High Flow Coefficients, Low Noise Emission

Compact, Robust Design:

– Minimum Mounting Space Required, Low Weight

Pneumatic Diaphragm Control Valve Specification.

1、Air Driven: The Compressed Air 5-7bar (Available With Hand Wheel)

2、Nominal Diameter: 20 ~ 200mm

3、Nominal Pressure 1.6 ~ 6.3Mpa

4、Suitable Temperature: -29 ~ +425 ℃

5、Flange Connection

6、Valve Structure: Single Seater, Sleeve, Three Links, Angle

7、Valve Material: Cast Iron, Carbon Steel, 316, 304

8、Valve Material: Alloy, 316, 304

9、Sealing Material: PTFE, Alloy

10、Suitable Medium: Gas, Water, And Oil Etc

11、Optional Accessories: Limit Switch, Solenoid Valve, The Valve Positioner

| Series | GKV1800C/GKV1600N/GKV1600H | |

|

Model Type |

Nominal Size (DN/NPS) | Nominal Pressure (PN/ANSI) |

| GKV1800C | DN15-100 / 1/2”– 4” | PN16-40 / Class 150-300 |

| GKV1600N | DN150-500 / 6“– 20“ | PN16-40 / Class 150-300 |

|

GKV1600H |

DN(15)25-200 / (1/2)1″-8″ |

PN63-250 / Class600-1500 |

| Characteristic | Equal Percentage Or Linear/Stem Guided,

Option: Integrated Double Guiding (Retrofit Able) /Equal Percentage Or Linear |

|

| Rangeability | 50:1 / 40:1 / 40:1 | |

| Plug Guide | Stem Guided, Option: Integrated Double Guiding (Retrofittable) For DN40-DN100(1/2″-4″)/Metal Sealing: IEC 50534-4 Leakage Class IV (0.01% Kvs-Value): Optional Leakage Rate V; Soft Sealing: IEC 50534-4 Leakage Class VI/Metal Sealing: IEC 50534-4 Leakage Class IV (0.01% Kvs-Value): Optional Leakage Rate V; Soft Sealing: (IEC 50534-4 Leakage Class VI Soft Sealing On Request) | |

| Seat Leakage | Metal Sealing: IEC 50534-4 Leakage Rate IV (0.01% Kvs Value): Optional Leakage Rate V; Soft Sealing: IEC 50534-4 Leakage Rate VI/ | |

| Bellows Seat(Optional) | Seamless, Double Walled, Made Of 1.4571; Opinion: Hastelloy And Other Materials | |

| Heating Jacket(Optional) | Connection DN 15 PN 40 (1/2″ ANSI 300) Flanges | |

| Low-Temperature Version(Optional) | Down To -196℃, With Cover Flange If Required | |